General Motor Applied Cold Rolled Silicon Steel

Basic Info

Model No.: 50W800

Product Description

1.Low iron loss

2.High magnetic flux strength

3.High lamination factor

4.Smooth surface

General Motor Applied Cold Rolled Silicon Steel Breif Introduction Cold Rolled Silicon Steel is steel with silicon added to it. The addition of silicon to steel increases its electrical resistance, improves the magnetic flux strength, and reduces the steel’s hysteresis loss. Hysteresis is the lag between the times when a magnetic field is first generated or applied to the steel and when the field fully develops. Through control of the grain size, the hysteresis loss of the steel can be accurately controlled. The direction of the grain in Silicon Steel can also affect its efficiency. The grain can be oriented in one or double direction (CRGO) through rolling to improve its density or the grain can be non-oriented and run in all directions (CRNGO), making the Silicon Steel less expensive. Production Flow Chart

Specifications 1. Grades: 50W800

Specifications 1. Grades: 50W8002. Thickness: 0.5mm&0.65mm

3. Width: 1000mm&1200mm

4. Inner Diameter: 508mm

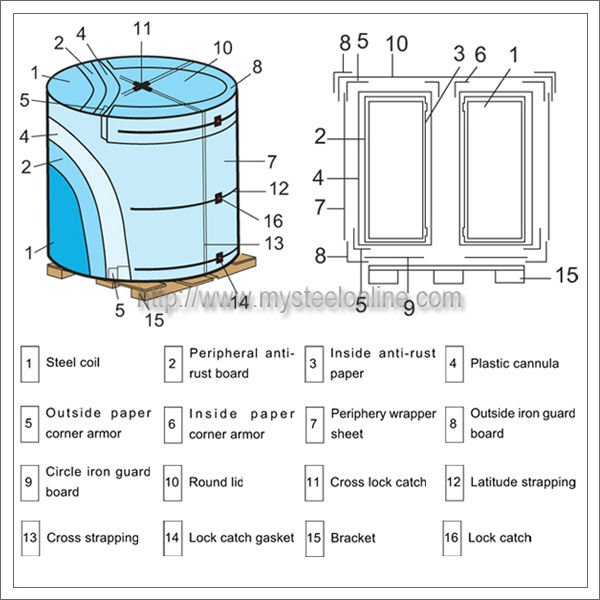

5. Weight of Steel Coil: 3-8MT Parameters 1. Density: 7.8kg/dm3

2. Iron Loss: 4.507W/Kg (f=50Hz B=1.5T)

3. Magnetic Flux Strength: 1.703T (f=50Hz H=5000A/M)

4. Interlayer Resistance: >10Ω.cm2/piece 5. Yield Strength: 250MPa

6. Tensile Strength: 360MPa

7. Extended Length 39% (380MPa)

8. HV1 Hardness: 122

8. Lamination Factor: 97%

9. Minimum number of Bends: 10Times Dimensional and Shape Tolerances

| Width (mm) | Thickness (mm) | Thickness tolerance (mm) | Longitudinal thickness tolerance (mm) | Traverse thickness tolerance (mm) | Width Tolerance (mm) | Flatness (%) |

|

800-100 | 0.35 | ±0.03 | ≤0.02 | ≤0.02 | +1.5 0 | ≤2 |

0.5 | ±0.03 | ≤0.03 | ≤0.02 | |||

0.65 | ±0.04 | ≤0.03 | ≤0.03 | |||

|

>1000 | 0.35 | ±0.03 | ≤0.03 | ≤0.02 | +1.5 0 | |

0.5 | ±0.03 | ≤0.03 | ≤0.02 | |||

0.65 | ±0.04 | ≤0.04 | ≤0.03 |

Applications 1. Compressor Motor 2. General Motor

Applications 1. Compressor Motor 2. General Motor3. Small Precision Motor

4. Small Power Transformer

5. Welding Transformer

6. Voltage Regulator Certificates

Quality Control & Test Instruments

Quality Control & Test Instruments  Production Line

Production Line  Factory Overlook

Factory Overlook  Superiority 1. Low iron loss, high magnetic flux strength, comes up to the international advance standard.

Superiority 1. Low iron loss, high magnetic flux strength, comes up to the international advance standard.2. Slight thickness difference between the horizontal and the longitudinal directions, promising the high lamination factor.

3. Insulating coating: uniform color, good insulation, strong adhesivity, high heat resistance, high imputrescibility.

4. High accuracy dimension and excellent mechanical property are convenient for the users to slit, cut and laminate.

5. Smooth surface, no rust, no rolling marks, no cold lap, no crease, no bubble cell, no delamination defects.

6. Has been SGS approved, in accordance with various domestic and international environmental regulations. Contact us if you need more details on Cold Rolled Silicon Steel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cold Rolled Silicon Steel Coils、Cold Rolled Silicon Steel Sheets. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Silicon Steel > Cold Rolled Silicon Steel

Premium Related Products