Food Cans Used JIS G3303 MR Grade T3 2.8/2.8gsm Tinplate Coils and Sheets

Basic Info

Model No.: SPTE

Product Description

Tinplate Specification

1. Available Thickness: 0.15-0.5mm

2. Thickness Tolerance: 0.006mm

3. Available Width: 300-980mm

4. Width Tolerance: 0-1mm

5. Inner Diameter: 420 & 508mm

6. Weight of Electrolytic Tinplate Coil: 3-10MT

7. Available Temper Grade: T1, T2, T3, T4, T5, DR8, DR9

Tinplate Application 1. Majorly used for packaging foodstuffs and beverages.

2. Used in containers for oils, grease, paints, polishes, chemicals and many other products.

3. Aerosol containers and caps and closures are also made from Tinplate Coils.

4. Electrodes, Cable tape, Magnetic screen covers, etc.

5. Automotive oil filters, Automotive air filters, Gaskets, etc.

6. Gas meter internal components, Heat exchangers, cookware, shelving, etc.

Superiority (Why choose tinplate for metal packaging?)

1. Excellent Corrosion Resistance by selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents.

2. Excellent Paintability & Printability Printing is beautifully finished using various lacquers and inks.

3. Excellent Solderability & Weldability Tinplate Coils is widely used for making various types of cans by soldering or welding.

4. Excellent Formability & Strength by selecting a proper temper grade, appropriate formability is obtained for various applications as well as the required strength after forming.

5. Beautiful Appearance Tinplate Coils is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet. Tin Coating Weight for Tinplate

|

Type |

Designation of tin coating weight |

Min. average tin coating weight (gsm) |

Former Coating Designation |

|

Equal tin coating | 1.4/1.4 | 1.2/1.2 | #15 |

2.2/2.2 | 2.0/2.0 | #20 | |

2.8/2.8 | 2.45/2.45 | #25 | |

5.6/5.6 | 5.05/5.05 | #50 | |

8.4/8.4 | 7.55/7.55 | #75 | |

11.2/11.2 | 10.1/10.1 | #100 | |

|

Differential tin coating | 1.4/2.8 | 1.2/2.45 | #15/25 |

2.2/2.8 | 2.2/2.45 | #20/25 | |

2.8/5.6 | 2.45/5.05 | #25/50 | |

2.8/8.4 | 2.45/7.55 | #25/75 | |

2.8/11.2 | 2.45/10.1 | #25/100 | |

5.6/8.4 | 5.05/7.55 | #50/75 | |

5.6/11.2 | 5.05/10.1 | #50/100 | |

8.4/11.2 | 7.55/10.1 | #75/100 |

Chinese Standard | Japanese Standard | American Standard | European Standard |

GB/T 2520-2008 | JIS G3303-2008 | ASTM A623M-06a | DIN EN10202-2001 |

T1 | T1 | T1 (T49) | TS230 |

T1.5 | -- | -- | -- |

T2 | T2 | T2 (T53) | TS245 |

T2.5 | T2.5 | -- | TS260 |

T3 | T3 | T3 (T57) | TS275 |

T3.5 | -- | -- | TS290 |

T4 | T4 | T4 (T61) | TH415 |

T5 | T5 | T5 (T65) | TH435 |

DR-7M | -- | DR-7.5 | TH520 |

DR8 | DR8 | DR8 | TH550 |

DR-8M | -- | DR-8.5 | TH580 |

DR9 | DR9 | DR9 | TH620 |

|

Properties |

Tin Coating Weight (gsm) | ||

2.8 | Over 5.6 | ||

|

Bare Corrosion | Rust Resistance | good | excellent |

Acid Resistance | good | good | |

Alkali Resistance | fair | fair | |

Black Sulfide Stain Resistance | fair | fair | |

Stress Cracking Resistance | excellent | excellent | |

Paintability | good | good | |

Corrosion Resistance after Painting (2) | excellent | excellent | |

Filiform Corrosion Resistance | excellent | excellent | |

Paint Adhesion | good | good | |

Formabity | excellent | excellent | |

Solderability | good | excellent | |

Weldability | good | good | |

Heat Resistance (3) | good | good | |

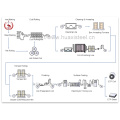

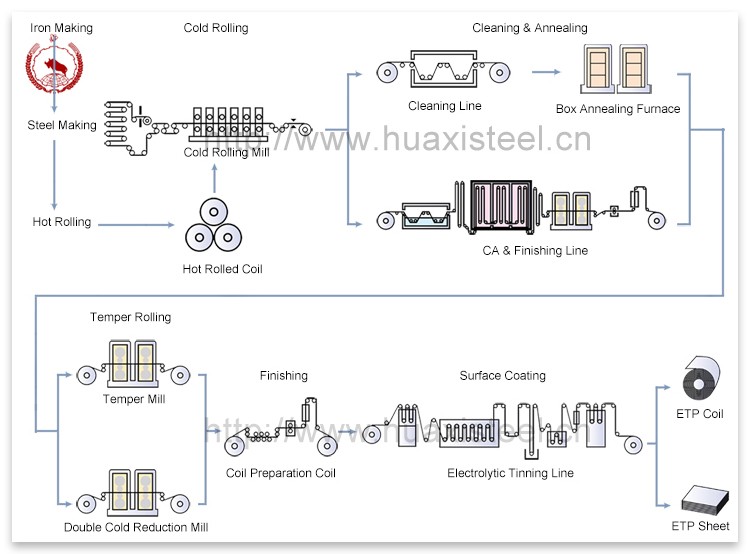

Production Line

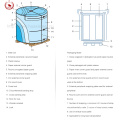

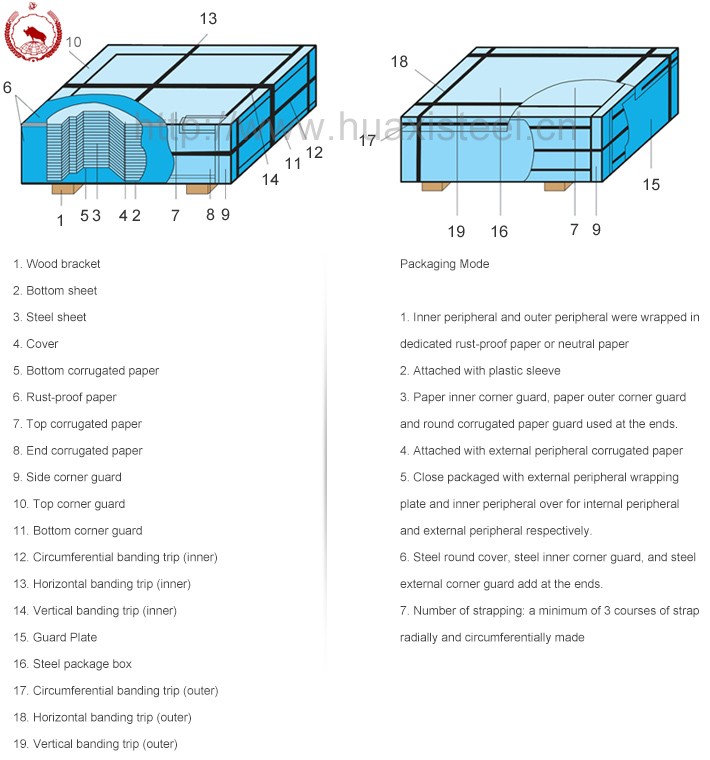

Production Line  Seaworthy Package

Seaworthy Package  Certificates

Certificates  Quality Control & Test Equipments

Quality Control & Test Equipments  Factory Overlook

Factory Overlook  Contact us if you need more details on Tinplate Coils. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tinplate Sheets、Jis G3303 Tinplate Coils. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Tinplate Coils. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tinplate Sheets、Jis G3303 Tinplate Coils. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Tinplate Coil

Premium Related Products